Sheetmetal Modeling & Drafting

Creating sheet metal drawings, engaging in reverse engineering processes, and developing fabrication drawings are crucial steps in various industries, particularly in manufacturing and engineering. Here's a brief overview of each:

Sheet Metal Drawings:

1. Overview:

Purpose: Sheet metal drawings serve as detailed guides for fabricating components from thin metal sheets.

Content: Includes dimensions, tolerances, material specifications, bend allowances, and surface finishes.

Tools: Created using Computer-Aided Design (CAD) software for accuracy and precision.

2. Key Components:

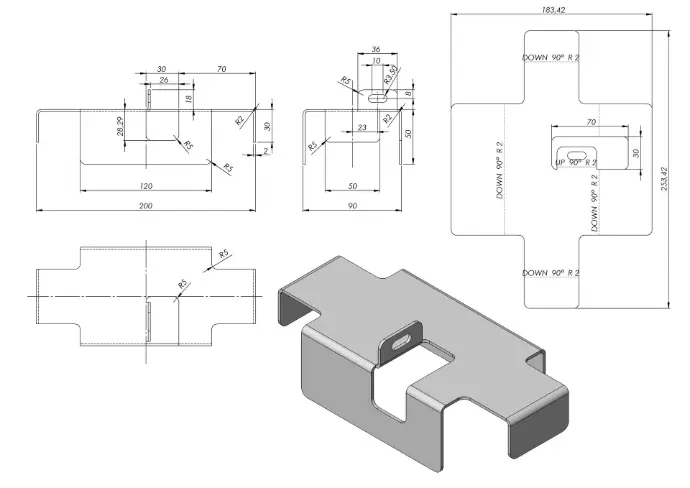

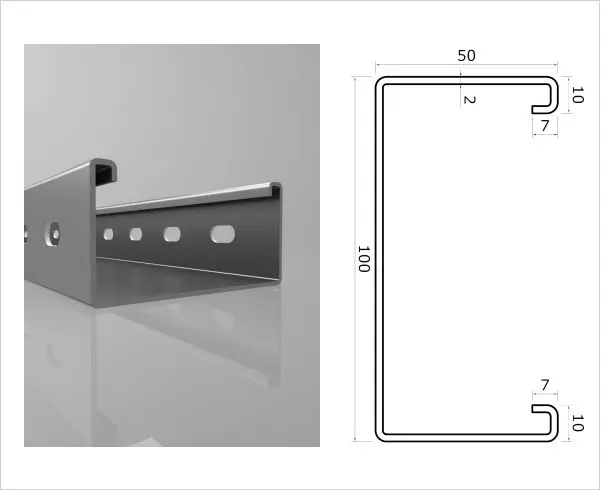

Flat Pattern: Depicts the 2D layout of the sheet metal part before bending or forming.

Bend Lines and Angles: Clearly defines where the sheet metal is bent and the angle of the bends.

Holes and Cutouts: Specifies the locations and dimensions of holes and cutouts in the sheet.

3. Importance:

Precision: Ensures accurate fabrication and assembly of sheet metal components.

Efficiency: Facilitates streamlined manufacturing processes by providing a clear roadmap for production.

Sheet Metal Drafting Process Flow

- Gather project requirements and specifications.

- Create initial design concepts and sketches.

- Select the appropriate material for the design.

- Develop detailed 2D or 3D drawings with accurate dimensions.

- Calculate bend allowances and unfolding details.

- Prepare the drawing for client review and approval.

- Make necessary revisions based on client feedback.

- Finalize the design and prepare for manufacturing handoff.

Sheetmetal Drafting-FAQS

Our detailing services for sheet metal fabrication cater to a variety of sectors, including construction, aerospace, automotive, energy, HVAC, manufacturing, electronics, food and beverage, marine, retail, and medical equipment.

Our team utilizes parametric CAD modeling methodologies through software such as SolidWorks Sheet Metal, AutoCAD, and Inventor to create precise sheet metal components, ensuring accurate bend allowances and flat patterns.

The integration of advanced CAD SOFTWARE technology with comprehensive Design for Manufacturing (DFM) and Design for Assembly (DFA) processes guarantees that each design is refined for both cost efficiency and manufacturability.

Designs are refined through the development of precise flat patterns that incorporate all essential bend lines and annotations, thereby facilitating efficient and accurate CNC operations.

Advantages of Sheet Metal Design Services:

Enhanced Efficiency: The design of sheet metal optimizes the manufacturing workflow, minimizing resource waste.

Bespoke Solutions: Customized designs effectively address particular manufacturing obstacles.

Economical and Prompt: Our services are cost-effective and provided swiftly by our skilled in-house professionals.

Diverse Design Proficiencies: We facilitate straightforward prototype creation, ideal metal selection, accurate sheet cutting design, and streamlined parts and assembly design.

Start to build your robust projects with our powerful engineering solutions

Engineering outsourcing solutions for your business.