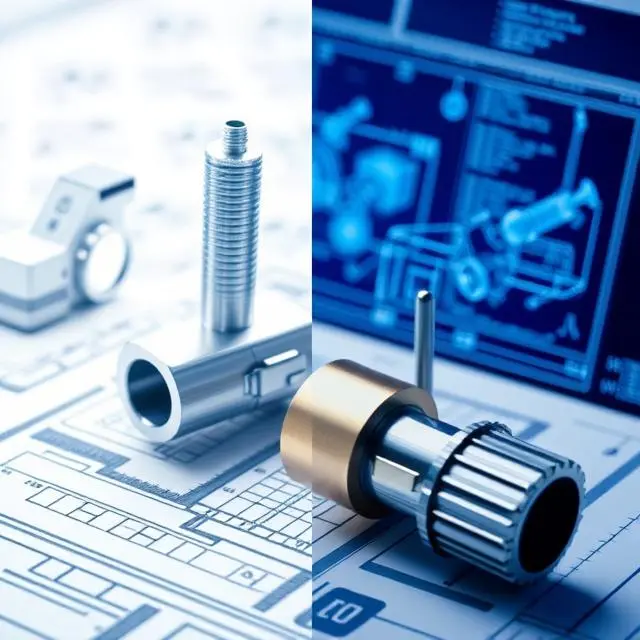

Reverse Engineering Design & Drafting

Creating sheet metal drawings, engaging in reverse engineering processes, and developing fabrication drawings are crucial steps in various industries, particularly in manufacturing and engineering. Here's a brief overview of each:

Reverse Engineering:

1. Overview:

Purpose: Reverse engineering involves disassembling a product to understand its design and functionality.

Process: Analyzing and measuring an existing object to create detailed CAD models and drawings.

Applications: Used for product improvement, replication, or understanding competitor products.

2. Key Components:

3D Scanning: Captures the physical geometry of an object to create a digital model.

CAD Modeling: Transforms scanned data into a digital representation of the original object.

Documentation: Creation of detailed drawings and specifications based on the reverse-engineered model.

3. Importance:

Innovation: Enables the improvement or modification of existing products.

Legacy Products: Valuable for recreating parts of discontinued or hard-to-find items.

Competitive Analysis: Gain insights into competitors' products for market research.

Reverse Engineering Design & Drafting - FAQs

Reverse engineering involves analyzing an existing product to recreate its design and develop accurate 3D models and technical drawings, often used to replicate or improve the product.

It helps recreate discontinued parts, improve existing designs, and enhance functionality. It’s also useful for modifying a product when original blueprints are unavailable.

Common tools include 3D scanning, CAD software (such as SolidWorks, AutoCAD), and laser scanning for accurate measurements and model creation.

Reverse engineering recreates an existing design, while fabrication drafting focuses on creating original designs for manufacturing from scratch.

When using advanced 3D scanning and CAD software, reverse engineering can be highly accurate, often within micrometers of the original part.

Yes, reverse engineering can be applied to intricate or complex designs, including machinery, tools, and even consumer electronics.

Challenges include handling imperfect or degraded originals, ensuring legal compliance, and achieving precise measurements for complex parts.

Advantages of Reverse Engineering Design & Drafting Services:

Replacement for Lost Designs

- Recreates original parts and products when the design files or blueprints are unavailable, ensuring continued functionality without starting from scratch.

Cost and Time Savings

- Speeds up the design process and reduces costs by using existing products as a basis for redesign, avoiding unnecessary prototyping and development.

Improves Product Performance

- Analyzes and enhances current designs, leading to better functionality, efficiency, and durability in the final product.

Supports Innovation

- Facilitates product upgrades and innovations by integrating new features while maintaining compatibility with existing systems or technologies.

Start to build your robust projects with our powerful engineering solutions

Engineering outsourcing solutions for your business.