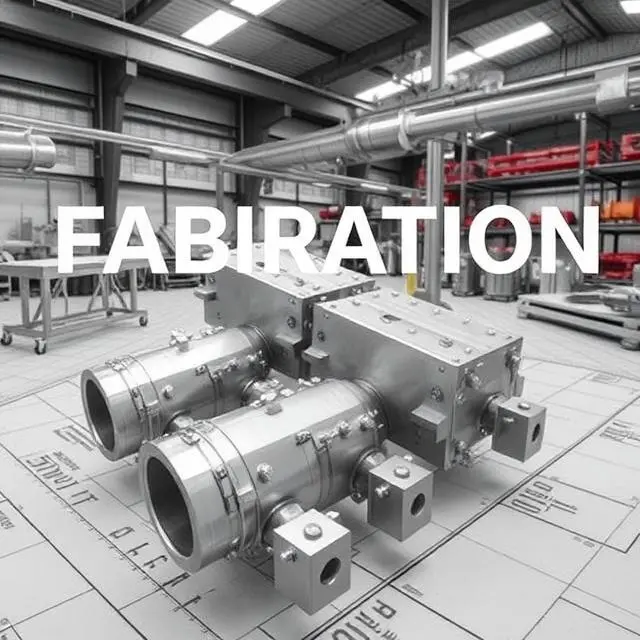

Fabrication Design & Dafting

Creating sheet metal drawings, engaging in reverse engineering processes, and developing fabrication drawings are crucial steps in various industries, particularly in manufacturing and engineering. Here's a brief overview of each:

Fabrication Design & Drafting:

1. Overview:

Purpose: Fabrication drawings provide detailed instructions for creating a product or structure.

Content: Includes dimensions, materials, welding symbols, surface finishes, and assembly instructions.

Tools: Developed using CAD software, ensuring precision and consistency.

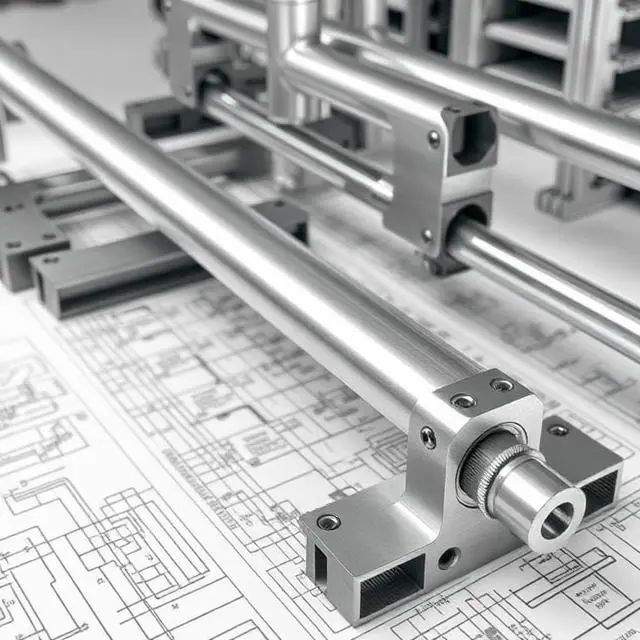

2. Key Components:

Assembly Views: Depict the assembled product from various angles.

Part Drawings: Detail individual components with dimensions and specifications.

Welding Symbols: Indicate the type and location of welds.

3. Importance:

Accuracy: Ensures that fabricated components meet design specifications.

Communication: Serves as a communication tool between designers and fabricators.

Quality Control: Guides inspectors and fabricators in maintaining quality standards.

Fabrication Design & Drafting-FAQS

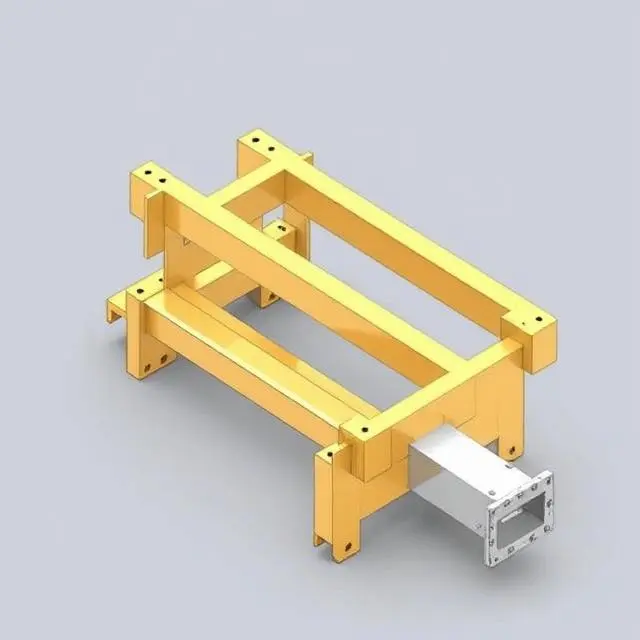

Fabrication design and drafting involve creating detailed 3D models and 2D drawings for the manufacturing of parts and assemblies. These documents provide the necessary specifications, dimensions, and instructions to guide the production process.

CAD (Computer-Aided Design) is used for its precision, flexibility, and ability to create detailed 3D models and 2D drafts. It helps visualize parts, detect design errors, and generate accurate production plans, saving time and reducing errors.

Detailed drafting ensures clear communication of the design, minimizes misunderstandings, provides precise dimensions, and outlines the necessary steps for fabrication and assembly, leading to higher-quality results and fewer production issues.

Contact a fabrication design service provider, share your project specifications, and work with their team to create the necessary CAD models and drafts. Many services offer customized solutions depending on your industry and project needs.

Fabrication drafting provides clear, accurate instructions for every step of the manufacturing process, reducing errors and delays. This leads to faster production times and more efficient use of materials.

Yes, fabrication design services are equipped to manage complex projects, including intricate designs, custom parts, and advanced manufacturing processes like welding, machining, and CNC fabrication.

Advantages of Fabrication Design & Drafting Services:

Precision & Accuracy: CAD models and detailed drafts reduce errors, ensuring accurate designs and efficient material use.

Time & Cost Savings: Quick design revisions, reduced rework, and efficient resource allocation speed up production and lower costs.

Improved Communication: Clear documentation and detailed plans enhance coordination between design, engineering, and fabrication teams.

Faster Production: Streamlined manufacturing processes and rapid prototyping lead to quicker turnaround times.

Start to build your robust projects with our powerful engineering solutions

Engineering outsourcing solutions for your business.